Case Studies

With over 15 years' experience specifying and supplying pumps, we have probably delivered a solution like yours before. Take a look at just some of our past projects.

Viscous Tomato Paste – Food Grade Drum Pump

A manufacturer and supplier of bulk food pastes and marinades to the catering industry contacted Castle Pumps Ltd with a food processing pump enquiry for their production facility. They were looking to pump sundried tomato paste from their processing machine, where the sundried tomatoes get chopped into the blend, into 15kg buckets that are then supplied as the final product. The challenge of this particular food transfer pump requirement is the product itself that is being handled.

Tank Wash Company - Plunger Pump

Castle Pumps received an enquiry from a UK based company that specialise in the cleaning of the inside of tanks and tankers. They required a high pressure pumping system that would efficiently supply hot water (around 85°C) to their tank cleaning heads at around 50bar of pressure and 170 litres per minute, allowing them to clean tanks with minimum effort. The key here was reliability as the pump is relied upon heavily for them to carry out their day to day business operations.

Metal Foundry Dust Laden Water – Peristaltic Pump

Castle Pumps received an enquiry from a metal foundry in America. They were looking to pump water containing up to 2 ¼ lb of foundry dust per gallon of water, making the fluid quite abrasive. This was to replace an existing pump on site that had come to its end of life and they wanted something lower maintenance. It also meant that ideally it would fit into the 2 ½” pipework already installed. and run 5 days a week, 24 hours a day.

Water Treatment Dosing – Peristaltic Pump

Castle Pumps received an enquiry from a company who deal with the collection and treatment of domestic sewage systems and industrial waste. They were looking for a water treatment dosing pump for metering 5-10 litres of ferrous sulphate and caustic soda at a time. Ferrous Sulphate is commonly used as a coagulant in water treatment to bind particles in wastewater together to make them easier to remove, and then caustic soda raises the pH levels after the coagulants lower it.

Bilge Water Transfer – Progressive Cavity Pumps

One of our repeat clients, a supplier of parts to the marine market, approached us with an enquiry for three pumps for their customer. These were needed for the pumping of bilge water onboard a vessel. Water collected in the bilge of a ship is typically harsh in nature due to the presence of oily sludges, waste and debris that may be contaminating it. Therefore, unlike the clean water pumps they had onboard, a typical centrifugal pump is not suitable as it is likely to clog and leak.

Diesel Generator Feed – Gear Pumps

Castle Pumps received an enquiry from a client who specialise in the design, fabrication and installation of fuel systems and their pipework. They were working on a project for which they were fabricating two duplex pump sets that would be feeding rooftop generators from a bulk diesel tank. Duplex pump systems can be for duty assist, where two pumps contribute to the total output, or duty standby, where one pump acts as a back up in the event of a failure with the first.

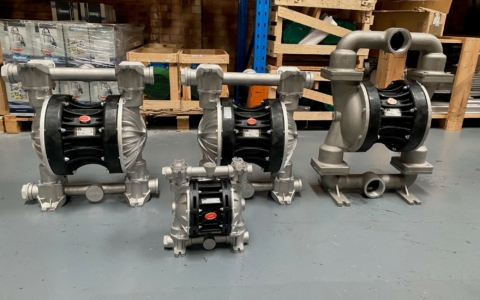

Solvents for Metal Reclamation – AODD Pumps

Castle Pumps were approached by a precious metal reclamation and recycling company looking for a number of the same pumps. They wanted a solution for transferring the solvents used for the cleaning of recycled metal product surfaces to be used in the pharmaceutical industry. The requirements of the pumps included being driven by air as opposed to an electric motor due to previous pumps used and being capable of offering a good service life despite the aggressive nature of the solvents.

Castor Oil For Resin Bound Aggregates – AODD Pumps

Castle Pumps received an enquiry from an aggregates company who produce a wide range of aggregates for landscaping, road surfacing and construction. They had already purchased some AODD pumps from us for one of their sites, and after being impressed with their performance were now back with an enquiry for similar pumps for a different site. They were building a new process for pumping castor oil.

Water Based Dye Transfer – Peristaltic Pumps

Castle Pumps have been working for a good few years now with a manufacturer of site machinery for the quarry, mining, aggregate and forestry industries. They originally approached us when they were in need of a pump to be used with one of their large-scale colouring trommels. The trommel works by moving mulch, wood chippings, aggregates and sand in large volumes along a conveyor whilst spraying it with dye to colour it for landscaping.

Ready to Drink Cocktail Producer – Flexible Impeller Pumps

We were approached by a manufacturer of ready to drink cocktails looking for pumps for the transfer of various fluids used within the recipes, as well as the finished product. The initial enquiry was just for two pumps, which they wanted to trial to see if it was worth upgrading all of their existing alcohol transfer pumps on site used for handling their drink products. After 6 months of excellent service, they returned with an enquiry for another 7 of the same pumps plus another pump for transferring 55% proof alcohol.

Bakery Fillings & Flavour Dosing – Food Grade Peristaltic Pumps

A bakery and confectionary goods producer contacted Castle Pumps looking for some pumps to help them move away from the manual handling of some of their ingredients, and upscale their production. There were two separate applications for which they needed solutions which Castle Pumps were happy to help with. Firstly, they required a pump for transferring the thick and sometimes solid laden fillings of their doughnuts and apple fritters.

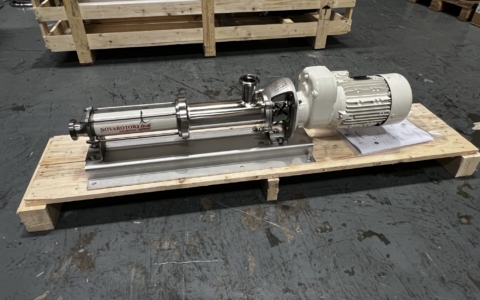

Soup Transfer – Food Grade Progressive Cavity Pump

Castle Pumps received an enquiry from a Stainless Steel fabricating company, who specialise in the design and manufacturer of equipment for the food processing equipment. A project they were commissioned to work on required a pump to be installed onto the equipment they were manufacturing, which we were happy to help specify. The pump was needed to transfer soup, which could contain both meat and vegetable pieces.